You are in the clock tips set of pages.

- Exploring Your New Old Clock

- You Are Here: Winding Your Clock

- Is Your Clock Ticking Evenly?

- The Winding Schedule: Living with a Wind-Up Clock

Winding Your Clock

Carefully determine which way to turn the arbors that wind the clocksprings.

Clocks can have a variety of holes in their face and it is important to know what they are for. Using the clock face below as a reference:

- The small hole near the 12 is for adjusting the speed of the clock. If your clock is not running, fussing with this will not help things, so leave it alone.

- On most clocks the larger hole near the 4 winds the spring that drives the time mechanism, i.e., the engine that makes the tick-tock sound and that makes the hands go around. The square post in there is called an "arbor" and it's what your key fits on.

- On most clocks the larger hole near the 8 winds the spring that drives the hourly strike mechanism, i.e., the gong sound that happens at the top of the hour and that gongs according to the number of the hour. The same key you used on the time arbor is used on the strike arbor. (Fun Fact: on some clocks the strike can get out of sync with the time, e.g., sounding 10 times at 3 o'clock. Let's not worry about that now.)

- Which way does the key turn? There is no hard and fast rule, so explore with gentle force on the key. In one direction, you should encounter a hard stop, that's the wrong way. In the other direction you might encounter one of the following situations:

- If you have resistance like a manual can-opener with clicks, that's good. If more winding yields more resistance/stiffness then it seems to be operating properly. No need to wind more than a few turns at this point.

- If it seems to spin freely and never gets stiffer, with or without clicks, you probably have a broken spring.

- If both directions feel like hard stops, you have a spring that is fully wound or an arbor that is frozen.

- If you have a time and strike arbor, they both probably turn the same way, but don't assume they do. Always use gentle force when exploring.

- Once you determine which way to turn the key and the arbor seems to be operating properly, give it four or five turns if it's not already a little stiff. If it's a little stiff, don't wind it any more. You don't need to "fully wind" a clock to explore function.

At this point, give your pendulum a nudge and it should start ticking. If it keeps ticking, and ticking evenly, congratulations! You might be interested in reading The Winding Schedule: Living with a Wind-Up Clock

If it keeps ticking, but is not ticking evenly, follow these instructions

If ticking does not occur or doesn't last for long, there are other things that are preventing proper operation. In this case, we hope you contact us to help you with your clock.

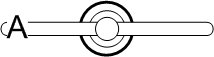

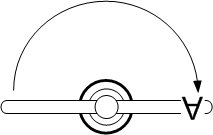

What is One Turn of a Key?

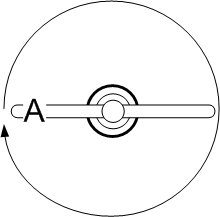

What Do Wound Clock Springs Look Like?

If you can get a look at your clocks springs, you can see how much they are wound.

Here are a couple more springs that are at different stages of being wound. For testing functionality, there is no need to wind either of these springs more.

- The spring on the left is almost fully wound. This clock could run for days with that much winding.

- The spring on the right is not wound as much. That spring drives the strike train and I'd guess that this clock would stop striking in a couple days.

Lastly, let's address the topic of "over-winding." In a properly functioning clock, it is our opinion that a careful person would not over-wind a clock. However, someone could, with careless application of force turn a key so hard that something breaks. When in doubt, stop winding.

There's also the case of a clock that is not functioning properly. In a case like that if someone were to force an arbor, something could break. When in doubt, do not wind.

Let's imagine a person who is winding a properly functioning clock. They will feel the spring getting stiffer and stiffer as they turn the key. At some point the key will get very hard to turn. It is conceivable that someone might choose to keep turning despite the increasing torque required. This could certainly break something. If you were to turn a key this hard, you probably knew you were doing something imprudent. When in doubt, stop winding.

Before attempting to wind a clock fully, you should carefully determine how many turns are needed to wind the clock to run for its specified run interval (e.g., 8 days.) This process is described on The Winding Schedule: Living with a Wind-Up Clock.